Repair of machine tools

Nowadays it’s hardly conceivable to have an effective production without modern CNC machine tools. Nevertheless, the best machine is only as good as its weakest component – this is always unpleasant as it means additional costs and shortfalls in production.

We, the service technicians of the Höhnberg Technik GmbH, repair lathes and milling machines of nearly every producer and with a common control system. This service includes all mechanical and electrical works.

Full service / Repairs

Details

- Functional diagnosis and error removal

- Mechanical and electronical repairs

- Repair of monitoring systems of Siemens, Fanuc and Heidenhain

- Replacement of linear guidings, screws, spindles, measurement systems, belts, sealings and other components

- Preparation of machine transports

- Commissioning of new and used machines

Machine geometry

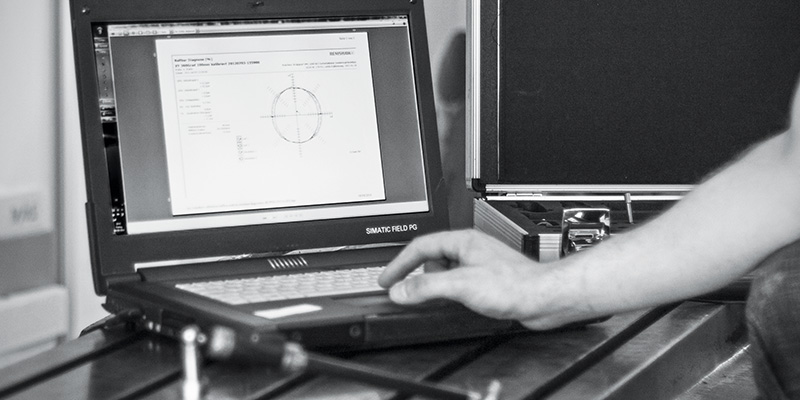

How precise are your parts? Exactly, just as good as the setting of your machine. In order to meet your requirements, the geometry should be checked and readjusted periodically. Different factors as temperature changes, wear and tear or collisions lead to inaccuracies in the machine. We give you an overview of the condition of your machine and, in cooperation with you, develop an action plan to remove the problems. This will reduce your reject rate and saves you valuable time.

Details

- Determination of the current state

- Realization of circle shape tests with Renishaw QC20W

- Adjustment of the geometry of milling machines and lathes

- Adjustment of the kinematics in 5-axes milling machines with Heidenhain control system

- Fixing the machines after a collision

- Development of a measure plan in case an adjustment is not possible

Maintenance

Do you use your machines 24 hours a day? Good! Unfortunately, this means many operating hours and an increased attrition of the single components. We offer you maintenance and inspections according to your needs. In order to prevent failures due to attrition our technicians check your machines carefully.

Details

- Inspection of the machine’s technical condition

- Creation of a maintenance plan according to the manufacturer specifications

- Implementation of all necessary works

- Replacement of wear parts

- Precision adjustment

- assistance during the production restart

Spare part service

Many components of a machine consist of standardized parts that can be supplied from alternative producers. The quality and the accuracy of fit are equal to those of the original parts. It often happens that parts can be repaired, so there is no need to replace them or it is possible to postpone the exchange to a later date – The result is the reduction of your maintenance and standstill costs to a minimum.

Details

- Delivery of mechanical and electrical spare parts: ball screws, axes drivers, linear guidings, displays, power contactors, straps etc.

- Determination of the necessary spare parts of older machines

- Conversion of parts in case the manufacturer is no longer available or the parts are too expensive

Backup service

Who doesn’t know? You’re taking the most beautiful holiday pictures and suddenly the memory card breaks. Even Machine tools have a data storage, which is breakable at any time. As the spare parts are very expensive and the machine cannot be used for several days, this is always connected with anger and frustration. Additionally, there is the loss of programs and machine data.

Especially the programs contain the know-how you developed for years, which makes them essential for your company. Moreover, a loss of the machine data means enormous costs and long down times as well. We offer a regular machine data backup and, optionally, the safe storage so in a case of emergency there won’t be unpleasant surprises.

Details

- data backup for monitorings of Siemens, Fanuc and Heidenhain

- preparation of complete system backups for monitorings with hard drive

- upon request filing of the backups on our servers

- preparation of a backup data medium (e.g. USB stick, CD/DVD, external hard drive)